In the early 80’s, H. H. (Hoot) Haddock was working in Prudhoe Bay, Alaska where the temperature is below zero all winter and goes to 60 below at times. Workers were living in units built with standard 6 inch walls. On the coldest days, Haddock could write his name in the frost on the interior walls. Haddock noticed that the modules where he was working had no frost on the inside walls. The modules had 1 ½ inch panels made with sheet metal on both sides of foam. Haddock was project manager working with a group of engineers. He and some of the engineers made the decision to build panels using plywood or oriented strand board (OSB) as skins with a foam core. When it came time for preparation to open business to manufacture the panels, only Haddock and one engineer remained who passed away shortly thereafter. In 1984, Haddock and his wife, Ann began business, opening a manufacturing plant in Wasilla Alaska.

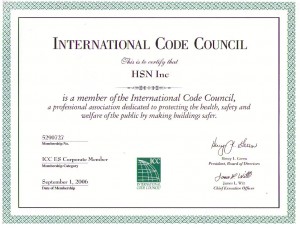

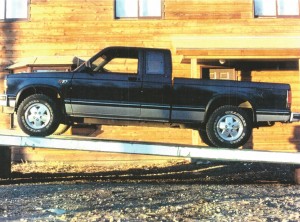

Haddock designed the equipment to manufacture the panels. His wife named their structural panel building system and also worked in their first ThermaSAVE plant. The first panel house went up in 1984, located in Wasilla, Alaska, in which his daughter still lives. There are heavy snow loads and it is said that higher winds than Florida and more earthquakes than California happen in Alaska . When Haddock first began, he had difficulty getting building departments to accept the system. All building departments are members of ICC. He began process to obtain an ICBO approval which was the code agency for the Northwest at that time. When all required tests are passed and accepted, a report is then issued to the applicant. This process took several years to accomplish. After 4 years and more cost than imaginable. The ICBO Report # PFC-4645 was obtained in 1989.

At that time, OSB was used as skins for ThermaSAVE panels. Haddock and his family left Alaska in 1990 due to the economy and moved to Washington State where he began testing with fiber cement board as panel skins as a product to replace OSB and eliminate the moisture problems connected with OSB. In the late 1990’s, Haddock began the process of qualifying the fiber cement board by passing all of the required testing. In 2004, the fiber cement board was qualified. With the tests results on the cement board, Haddock was able to use the same span charts which were in the original report. To our present knowledge, ThermaSAVE is the only panel which has passed the cement board tests for ICC approval. When all code agencies were combined, the uniform building code became ICC (International Code Council). The ICC Evaluation organization writes the building codes. The report number for our ThermaSAVE Panels is now ICC Report # 2406.

The approval report allows us as the owner of the report to stamp all panels showing our ICC report number, ThermaSAVE as the manufacturer and the ICC approved, bonded and licensed quality control company. Our quality control company performs periodic inspections at our manufacturing plant. This stamp shows the assurance of the 3 different entities that ThermaSAVE is an ICC approved quality product and will perform as stated in the ICC Report # 2406. Florida has added an addendum to their state code which addresses requirements for different applicable wind zones depending on the structure’s location. California also has a similar addendum relating to earthquakes. ThermaSAVE has passed testing for Florida’s highest wind zone and also for earthquakes. (View our earthquake test) There were several plants set up to manufacture the ThermaSAVE panels. These were licensed and listed as a manufacturer on ThermaSAVE’s ICC Report # 2406. As a result of the economic downturn, none were in a position to survive with the exception of Haddock’s plant in Florence, Alabama.

Haddock continues to set up plants, licensing them to use his ThermaSAVE Technology to manufacture the ThermaSAVE Building System. There is domestic and great international interest especially in purchasing plants and becoming licensed to use the ThermaSAVE Technology to manufacture the panels. Through Haddock’s company is the ONLY way a license can be obtained to use his ThermaSAVE Building System Technology. There is no other way. The ICC is accepted internationally which is a great advantage to all of our licensees.